Custom Handmade

FLUTES

SOUND

ROBUST & PROJECTING

BURKART SCALE

PROPRIETARY GOLD SOLDERS

custom

OPTIONS

Made for You

C# Trill Key

Split-E Mechanism

D# Roller

HAND-ENGRAVED DESIGN WORK

Burkart BAM Case

Designed to offer superior shock absorption and maximum protection, this sleek and durable case is the perfect upgrade for your Burkart flute.

Additional Customizations

FEEL

Burkart’s innovative micro-Link™ architecture provides unmatched stability and elegance. Two 14K white gold rods reduce the weight of the mechanism and allow for light and balanced tension throughout with lightning-fast response.

precious

MATERIALS

More Than Beautiful

Platinum

(Elite Only)

14K Gold

(Elite Only)

10K Gold

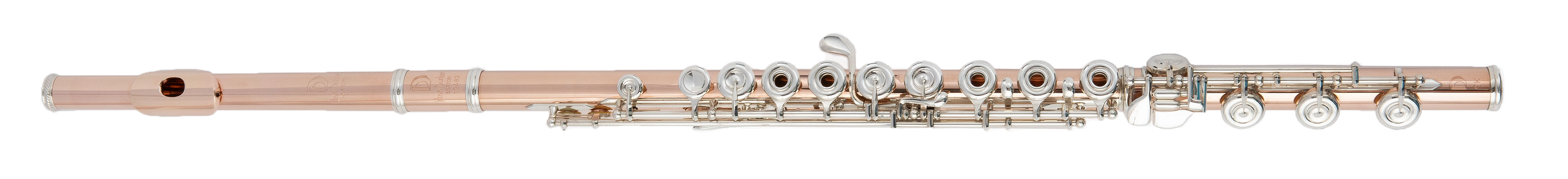

The 10K rose gold flute offers the flutist the opportunity to explore the added depth of gold while retaining the beautiful brilliance of a silver flute. The 10K gold Elite flute is made with solid gold tubing in a 0.014″ wall thickness, silver tone holes, rings, and keywork.

(Elite Only)

9K Gold

(Professional Only)

9KAG Gold on Silver

(Professional & Elite)

595 Platinum Enhanced Silver

(Elite Only)

998 Silver

Our 998 silver flute has the tonal depth, color, and projection of a platinum flute, the warmth of a gold flute, and yet speaks with the shimmer and brilliance of a silver flute. The resonance of this flute is the result of its extraordinary 99.8% pure silver tube that is both hard and reflective. Hardness imparts vibrancy, color, and a beautiful distinctive sound.

(Elite only)

Sterling Silver

Burkart’s standard silver flutes are made of sterling silver (92.5%). Tubing thicknesses of 0.016” exemplify a solid, warm timbre, while a thickness of 0.018″ lends a darker, more robust sound to the sterling silver flute.

(Professional & Elite)

introducing

THE BURKART BAM CASE

Beautifully designed with durable ABS exterior and black velvet interior. The case shell is made with the BAM Hightech technique: a triple-ply structure made of high performance materials. An injected high-density polyurethane foam interior provides superior shock absorption.

Male/Female airtight seal and single flat latch with lock and key. Standard case size fits perfectly in our signature Burkart leather case cover.

Available for standalone purchase or as an upgrade for your pre-owned Burkart flute. The Burkart BAM Case now comes standard with all newly purchased Burkart flutes.

YOURS

Elite Soldered

World-renowned, custom handmade flute with soldered tone holes with many options and all metals.

Starting at $14,500

Professional Drawn

Custom handmade, drawn tone hole flute available in sterling silver, 9K Gold on Silver, and Solid 9K Gold.

Starting at $10,600

we’re happy to help